Automation solutions

adapted to your business

We use our know-how for your need. With a strong heritage in the semiconductor and heat treatment sectors, we have developed our expertise and offer customized solutions to meet your specific needs and environment. Below you’ll find a selection of some of our achievements and standard solutions. We look forward to find out on your challenge and on any other application!

Heat

Treatment.

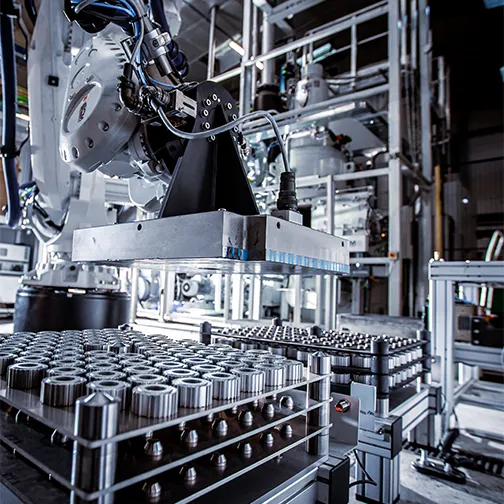

The ECM Group’s core business, heat treatment, combined with our robotics expertise, has made us the unique provider for robotized heat treatment systems. We offer a complete range of solutions to perfectly adapt to your heat treatment line, whether or not it is integrated into your production flow. Some of our automated solutions :

- Load building cell with 2D/3D vision and tool changeover

- Furnace loading/unloading cell

- Robotic bulk processing – basket

- Automated distortion control following heat treatment

- AGV transport of processed loads

Whether for automotive loads of up to 1500kg or vacuum furnace loading of brazed parts (fragile loads), our expertise in gripper development enables us to address any type of heat treatment.

Solutions for

Batteries.

ECM Robotics can help you to manufacture and automate your battery pack assembly and welding processes. This turnkey solution guarantees quality, repeatability and profitability. The solution covers all stages of the battery pack manufacturing value chain:

- Control : automated measurement of the electrical voltage of each cell prior to the assembly phase.

- Assembly : cells that have been checked for conformity are automatically assembled into battery packs.

- Welding: assembled cells are spot-welded using resistance welding.

- Tracking : welding data for each cell is recorded and identified, and sent to a centralized supervision system.

ECM recently delivered a turnkey solution for the electrification of urban vehicles in India. This solution, which includes engineering, technology transfer and installation, integrates the assembly, testing and welding of battery packs for these urban electric vehicles.

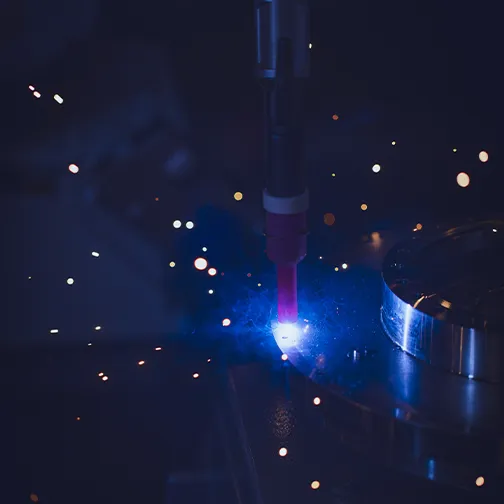

Welding

Robots.

Selecting a robotic welding station guarantees maximum productivity while controlling your costs and process quality. Whether you’re looking to automatize your TIG / Arc welding / MIG MAG welding stations, ECM Robotics can provide you with the expertise you need to simplify your operations.

Adding a welding station can free up a skilled operator for more complex operations with added human value on live stations; and thus do away with skilled and sought-after labor for so-called repetitive tasks that can be substituted with a robotized welding system. We integrate our welding solutions both for high-tech applications in semiconductor processes and for welding operations on industrial boilermaking production lines.

Semi

Conductor.

Cleanroom integration for wafer handling is the birth activity of our robotics division. With a long background in the semiconductor and solar industries, and key know-how in handling fragile substrates at high speeds, we integrate our solutions to optimize and ensure high productivity in your processes.

Our expertise includes integration in a pure environment, as well as in a collaborative environment with the operator. Our semiconductor solutions target both R&D operations with piece-by-piece wafer handling (multi-size substrate), and larger-scale production operations with our cassette loading solutions.

Do you have a question or a project?

Would you like more information, to entrust us with a project or meet our teams ?

Fill in our form and our teams will get back to you as soon as possible!