End Effector

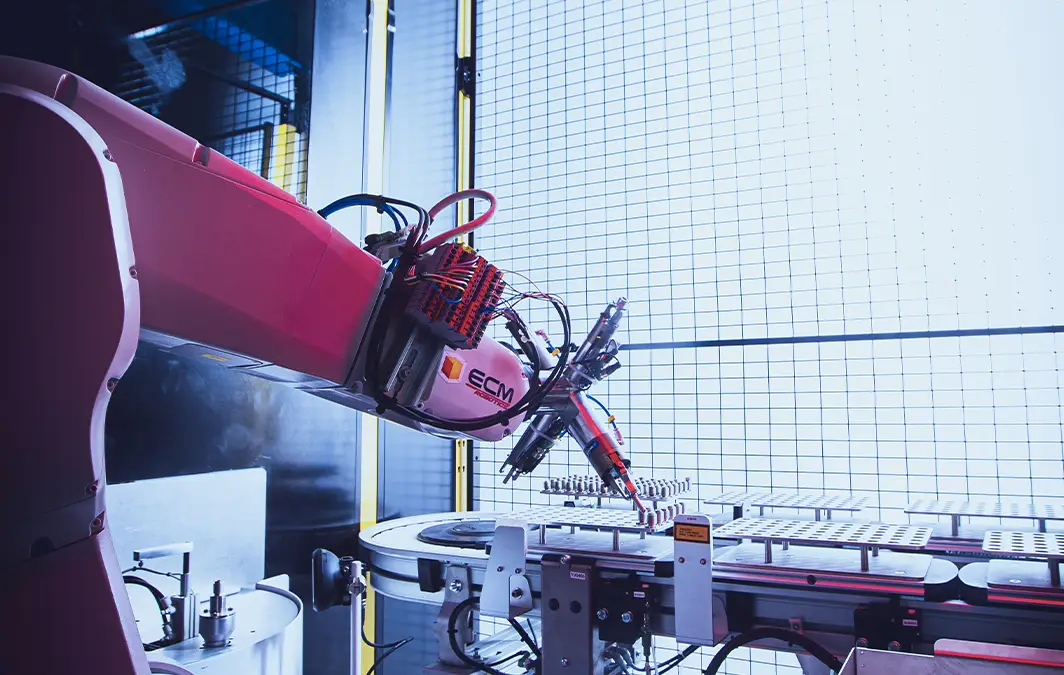

Custom End Effector Integration

At ECM Robotics, every end effector system is custom-designed to meet the specific contraints of your industrial processes. From the choice of gripping technology to material selection, our expertise in robotics and mechanical engineering ensures seamless, high-performance integration. As an industrial automation expert, ECM Robotics develops tailored systems to meet the needs of diverse industries such as automotive, aerospace, semiconductor, food processing, and more.

End Effector

Definition and use case

An end effector (or robotic gripper) is the terminal element of a robot, responsible for grasping, moving, or positioning parts within a production process. Its design focuses on optimizing clamping, friction and contact forces, taking into account part geometry, cycle constraints and precision requirements. Grippings technologies : pneumatic, electric, magnetic or vacuum, allow the system to be adapted to various production contexts, from high-speed handling to fine assembly or the manipulation of fragile components.

Mastered integration in

any environment.

ECM Robotics provides complete robotic integration, combining machine vision, end effector systems, autonomous mobile robots (AMR), and robotic handling cells. This comprehensive approach enables the design of fully customized solutions that integrate seamlessly into any industrial environment.

23 years of expertise

The different types

of End Effector.

With over 23 years of experience in gripping technologies, ECM Robotics masters every available end effector technology, adapting each solution to its specific application.

Pneumatic Grippers

Pneumatic grippers operate using compressed air to activate cylinders or gripping fingers. Robust and fast, they are ideal for high-throughput applications in packaging, plastics, or assembly industries. Their simple design ensures low maintenance and long-term reliability while allowing easy adaptation to different part sizes and shapes.

Magnetic Grippers

Magnetic grippers use a permanent or electromagnetic field to handle ferromagnetic parts. They are particularly suitable for handling sheets, machined components, or metal assemblies. Their main advantage lies in the absence of direct mechanical contact, reducing wear and deformation risks on the parts handled.

Electric Grippers

Electric grippers offer precise control of gripping force and positioning through integrated motors. This technology is ideal for flexible environments such as multi-product or collaborative robotic cells. Without the need for compressed air, electric grippers offer cleaner, quieter, and more energy-efficient installations.

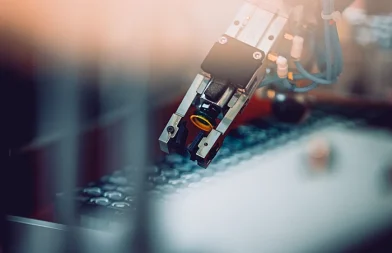

Vacuum Grippers

Vacuum grippers use negative pressure generated by a pump or ejector to pick up parts via suction cups. Based on Bernoulli or Venturi principles, ECM Robotics’ vacuum grippers employ controlled airflow to create stable lift, allowing efficient handling without surface contact. They are particularly effective for manipulating flat or delicate materials such as glass, plastic, or cardboard. Lightweight and modular, they integrate easily on small or medium-capacity robots, providing an excellent weight-to-performance ratio.

Gravity Grippers

Gravity grippers rely on the force of gravity or the part’s own weight to maintain grip, without pneumatic, electrical, or magnetic power. Simple, durable, and reliable, they are ideal for environments prioritizing safety and minimal maintenance, often used for transferring heavy, cylindrical, or complex-shaped parts.

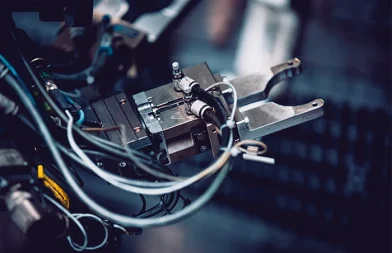

Custom End Effector

ECM Robotics designs fully customized end effectors based on the specific characteristics of the parts handled — size, weight, material, or fragility. With a complete engineering approach, from prototyping to commissioning, ECM Robotics ensures integration perfectly adapted to each client’s production needs and environment.

Prototyping and design

through 3D printing.

3D prototyping allows for testing, ergonomic adjustments, and system validation before production, reducing development time and cost. It also enables the exploration of complex geometries and specific materials tailored to client requirements.

Advantages of an End-Effector

Integrated in your production line.

The end effector is at the heart of robotic integration. By ensuring precise, fast, and reliable handling, it optimizes throughput, reduces cycle times, and minimizes positioning errors. Proper integration enhances safety and flexibility, ensuring full compatibility with your industrial process constraints.

Cycle time optimization

An optimized end effector minimizes handling time and increases production rates. By reducing unnecessary movements and ensuring precise grip, it improves the overall performance of robotic cells.

Reliability and repeatability

A well-integrated end effector ensures perfect repeatability of robotic movements. It applies the right pressure at the right time, minimizing the risk of dropping, deforming, or damaging parts.

Flexibility and adaptability

End effector systems can be designed to handle multiple part types or formats. This versatility maximizes robot utilization across various products without requiring major equipment changes.

Reduced maintenance and wear costs

A well-engineered end effector minimizes friction, shocks, and mechanical stress. This results in longer component lifespan and simplified maintenance.

Quality and safety

Stable and controlled manipulation ensures product conformity and reduces manual handling risks. Operator safety and process quality are therefore reinforced.

All our expertise

in industrial robotics.

Vision

Machine vision

systems.

ECM Robotics designs and integrates advanced machine vision systems, enabling your robots to detect, analyse and respond to their environment in real time. our solutions enhance the precision, efficiency and quality of your production processes.

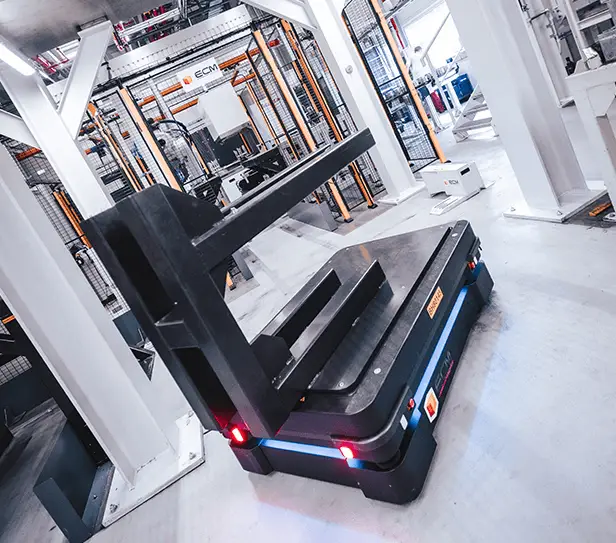

AMR

Autonomous Mobile

Robots.

Our AMR systems leverage advanced sensor, camera, lidar and navigation algorithm technologies to navigate your production lines. Their ability to map the environment in real time and adjust their trajectory ensures precise and high-performance automation.

Do you have a question or a project ?

Would you like more information, to entrust us with a project or meet our teams ?

Fill in our form and our teams will get back to you as soon as possible !