Vision

Machine Vision Integration

Machine vision systems play an essential role in automation and quality control. Discover how ECM Robotics integrates customized machine vision systems tailored to your production needs. With over 15 years of expertise in robotics integration, ECM Robotics designs and deploys customized vision solutions: 2D/3D localization, surface inspection, code reading, automated sorting, and applications based on AI and deep learning.

Robotics integration expert

What is Machine Vision ?

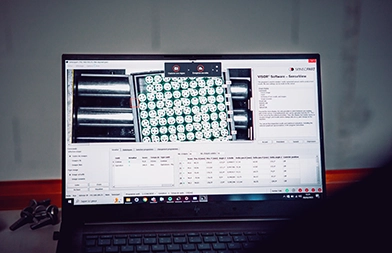

An industrial vision system combines cameras, sensors, and image analysis software to guide robots, control product quality, and automate complex operations.

This technology has become essential for industries seeking both performance and flexibility.

ECM Robotics : robotic

solutions integrator.

ECM Robotics designs comprehensive solutions combining industrial vision systems, gripping technologies, autonomous mobile robots (AMRs), and handling cells. This comprehensive expertise enables the development of flexible, high-performance systems that are perfectly suited to the specific needs of each industrial environment.

Vision technologies

Integrated by ECM Robotics.

ECM Robotics integrates advanced vision technologies to meet the specific needs of each industry. From 2D/3D localization to quality control, our solutions improve the accuracy, productivity, and reliability of automated processes.

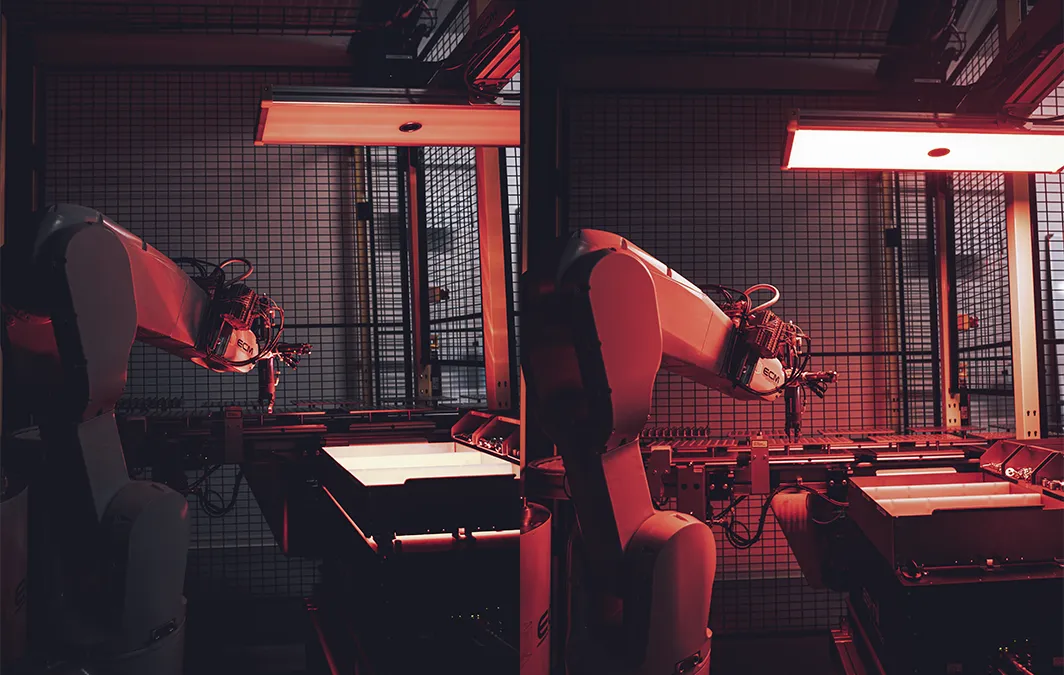

Embedded vision systems

ECM Robotics has expertise in the integration of embedded vision systems, which involves directly integrating a camera or vision sensor onto a robot. This allows the robot to adapt its movements and decision-making in real time. This technology improves guidance accuracy, facilitates the handling of parts with variable shapes, and enables the automation of complex tasks.

2D & 3D localization

2D and 3D vision systems enable precise spatial localization of parts, whether stationary or in motion. This industrial vision technology facilitates robotic guidance, automated assembly, and quality control.

Surface inspection

Using high-resolution cameras and advanced algorithms, surface inspection detects defects, scratches, or anomalies that are invisible to the naked eye. It ensures consistent product quality and reduces the risk of non-compliance.

AI & Deep Learning Applications

The integration of AI and deep learning into machine vision offers unprecedented analysis and recognition capabilities. These technologies enable systems to be adapted to complex environments and evolving tasks.

Code reading & traceability

Vision systems ensure reliable reading of barcodes, QR codes, or specific markings, even under difficult conditions. They enhance product traceability and facilitate tracking throughout the production chain.

Automated counting & sorting

Industrial vision enables fast and accurate counting of parts, as well as automated sorting according to defined criteria. This solution improves throughput, reduces human error, and optimizes production flows.

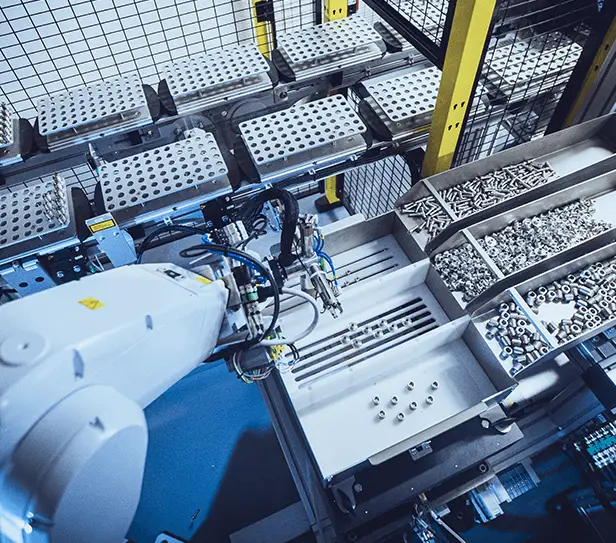

Robotic unloading

using 3D vision.

Optimize your production with an automated bulk handling solution combining industrial 3D vision and a 6-axis robot.

The system identifies the position of bulk parts in real time and the robot picks them up with precision, speed, and flexibility. Productivity increases and manual tasks are reduced. This solution adapts immediately to different types of parts.

Machine vision :

the benefits for your production.

The integration of machine vision systems brings tangible benefits to production environments. These technologies enable automated quality control directly on the production line, rapid defect detection, and accurate dimensional measurement. Combined with robotic guidance and code reading, they improve flow, reduce waste, and ensure complete product traceability.

Quality control

Machine vision allows each product to be inspected in real time, detecting dimensional, surface, or assembly defects. This reduces the risk of non-compliance at the end of the line.

Production flow optimization

Thanks to robotic guidance and 2D/3D localization, vision systems facilitate precise part handling and improve the fluidity of automated operations.

Reduction of scrap and rework

By identifying anomalies early on, machine vision limits material waste and costly rework, thereby improving overall yield.

Product traceability and tracking

Code and marking reading solutions ensure reliable tracking of components throughout the process, guaranteeing compliance and safety in production.

Discover our other

industrial robotics expertise.

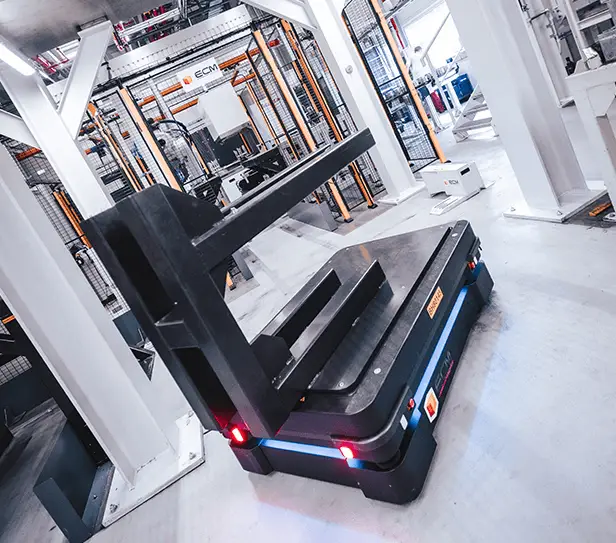

AMR

Autonomous Mobile

Robots.

ECM Robotics designs and integrates Autonomous Mobile Robots (AMRs) that can navigate freely and adapt in real time to your production environment. Our expertise ensures flexible and reliable solutions to optimize your logistics flows and automate your operations.

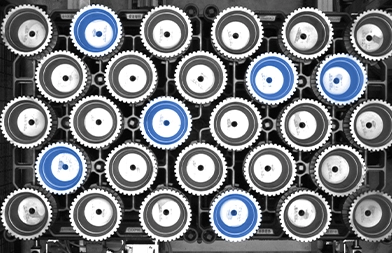

End Effector

Custom

End Effectors.

ECM Robotics develops custom end effectors tailored to each application, whether it involves delicate handling, sorting, or automated assembly. Our expertise ensures reliable and high-performance solutions, perfectly integrated into your production lines.

Do you have a question or a project ?

Would you like more information, to entrust us with a project or meet our teams ?

Fill in our form and our teams will get back to you as soon as possible!